5th Axis - Workholding Evolved

5th Axis products are high quality and designed to improve machine shop productivity.

Here are some ways:

- Increase pallet load

- Speed up job changes

- Decrease machine idle time

- Better access to the work piece

- Reduce Number of Operations

- Hold jobs with less

5th Axis prefers uses of dovetails as the method of holding. They use a 45° dovetail which gives equal down and inforce, holding jobs more stable than any other workholding method.

Vises feature jaws that have both serration (for softer materials < 35 HRC) and dovetails. They have 13microns of repeatability and max clamping force of 22.2 kN. They have a nice low profile design making machining of5 sides of a workpiece easy. Compared to a traditional vise not as much material is required to be clamped in orderto stay steady, so more of a work piece is machinable. Jaws are reversable, and vises can be direct mounted or be used with either 52mm or 96mm RockLock. Softjaws are available, as well as a built-in work piece stopper.

Dovetail Top tooling gives awesome holding power with a tiny foot print. This is perfect for 4 & 5 axis machining where access to the workpiece is a priority.

Bases include standard pallets, raised pallets, tombstones and pyramids. Most of these can be combinedtogether with the 52mm / 96mm RockLock system. This gives a huge amount of flexibility to help maximise yourproductivity no matter the job.

Check out the 5th Axis 3D Tool Configurator. 3D models are available for download as well, so you can plan your jobs out accurately.

Key Products

CONTACT US TO MAKE AN ENQUIRY

Australian Customer Examples

Send an enquiry to the Livetools Team or call us on 02 4017 0198

Self Centering Vises

Self Centering Vises Double Station Vises

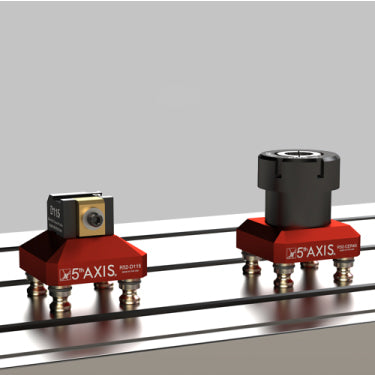

Double Station Vises  52mm RockLock

52mm RockLock 52mm Top Tooling

52mm Top Tooling  96mm RockLock

96mm RockLock 96mm Top Tooling

96mm Top Tooling